Operation method:

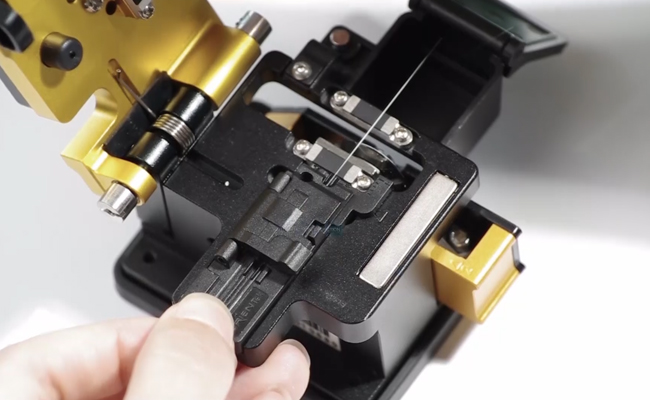

1. The optical fiber welding machine confirms that the slide plate of the blade of the optical fiber cutting machine is at one end in front of it, and opens the size pressing plate;

2, strip the optical fiber coating layer with the fiber stripping forceps, Set aside a length of 30-40 mm, wrap the fiber with alcohol-dipping cotton or cotton paper, and wipe it clean. Wipe with degreased cotton or cotton paper once, do not use the same degreased cotton or cotton paper for the second time (note: alcohol of purity greater than 99%);

3, after the edge of the optical fiber coating layer is aligned with the appropriate calibration on the cutter scale (12-20cm), The left hand puts the optical fiber in the guide groove of the optical fiber cutting machine, and requires the bare fiber to be placed directly on the left and right rubber pads.

4. Close the small press plate and the large pressure plate of the optical fiber cutting machine, and push the slider with the blade so that the blade cuts the lower surface of the fiber optic fiber. Slide freely to the other side and cut off the optical fiber;

5, hold the optical fiber cutter with the left hand, open the fiber chip with the right hand, and put it in a fixed container;

6, hold the optical fiber with the left hand and open the optical fiber cutter small press with the right hand, Carefully remove the ends of the fiber, note: clean fiber section do not touch other things.